USPS OIG issues safety alert on Methane Detection System

This management alert presents a safety concern of the methane detection system observed at the U.S. Postal Service Michigan Metroplex Processing and Distribution Center (Metroplex), located in Pontiac, MI This review was initiated based on safety concerns expressed to us in a complaint which identified five employee deaths during a 14 month period. We have not correlated these deaths to the safety concern at this time, but are continuing work in this area. However, we are reporting this issue with the methane detection system for your immediate action.

The Metroplex is built on a site previously used as a vehicle manufacturing plant that included a foundry.1 This site is considered a brownfield. Brownfields are former industrial or commercial sites where future use is affected by environmental contamination. Brownfield sites are converted into usable space under the supervision of the U.S. Environmental Protection Agency (EPA). The EPA has specific guidelines and regulations that must be followed to properly assess, safely clean up, and sustainably reuse brownfields.

Before the Metroplex site was developed into useable space, the landowner commissioned environmental studies to determine which contaminants were present and what remediation was necessary to remove or contain such contaminates. Light non-aqueous phase liquid (LNAPL)2 was one contaminate found in multiple underground locations throughout the site. As part of the decomposition process organisms underground break down LNAPL and produce colorless and odorless methane gas.

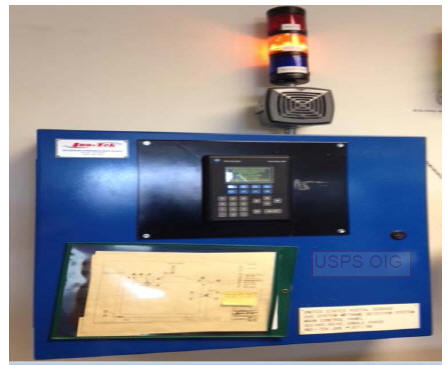

When the Postal Service built the Metroplex, a gas venting system was installed under the foundation and inside the building. The purpose of the venting system is to prevent the buildup and accumulation of methane gas underneath the building by actively capturing the gas and venting it away from the building. Additionally, a methane detection system (MDS) was installed with sensors strategically placed in various enclosed spaces within the facility. The MDS was designed to detect and alert personnel of any seepage and accumulation of methane gas inside the facility.

Methane gas is extremely flammable and may form explosive mixtures with air when levels reach certain concentrations known as “lower explosive levels” (LEL). Control of the explosion hazard is achieved by ventilation. In the case of the Metroplex, ventilation occurs through the gas ventilation system, which is built under the foundation and into the structure of the building. The LEL is also used as a percentage reading on the main control panel of the MDS. The system was designed and calibrated to detect and measure methane gas and shows the relative concentration of the atmosphere

Postal Service managers are required to demonstrate a commitment to providing safe and healthy working conditions. If methane builds up in enclosed spaces, the health and safety of employees may be at risk and could result in medical complications. Unmitigated accumulations of methane gas may increase risks to the health and safety of employees and could lower productivity and employee morale.

Methane Detection System

Based on our observations and review of the MDS log book, the methane detection system has not functioned properly since March 2015. Maintenance personnel documented in the log book attached to the MDS that 10 warnings (amber light flashings) occurred between March and July 2015. The LEL percentages, when annotated on the log book, ranged between 6 to 18 percent. According to the log book, the sensor was replaced in March 2015. A vendor’s invoice totaling over $2,000 shows that the vendor replaced the same sensor and recalibrated the system in September 2015, 6 months later. The vendor also provided maintenance personnel three sensors so that they could replace the sensors themselves.

When we asked maintenance personnel about the amber flashing light, we were told that the sensor was malfunctioning and personnel were waiting for the vendor to provide parts.

Upon further inquiry in January 2016, the vendor who routinely performed system maintenance and recalibrated the MDS and its components advised us that he repeatedly recommended the Postal Service resolve his claims of methane buildup. The vendor also recommended the Postal Service modify the system to include a ventilation of the pipes that release the methane gas into the atmosphere. At the time the warning lights were activating, the facility officials did not conduct an independent validation as the vendor recommended.

On January 15, 2016, management stated they have taken action by issuing an emergency contract for an industrial hygienist to evaluate the methane levels at the facility. According to a report detailing the results of the evaluation, the methane level was low and there is no immediate health or safety concerns identified with regard to the methane levels in the facility. They also stated they notified employees and unions of the risk and results of the evaluation. Management stated that their engineers are in the process of evaluating the system and they will follow-up to determine why there are repeated sensor failures.

Recommendations

We recommend the vice president, Network Operations:

1. Complete a review of the methane detection system to resolve any issues.

2. Establish an ongoing process to independently validate the results of the methane detection system on a periodic basis.

Management agreed with the finding and recommendations and stated there were never health concerns regarding the employees at the Michigan Metroplex. Management also agreed there are sensors on the methane detection system that appear to be in need of repair.

Regarding recommendation 1, management stated a qualified vendor will be contracted to evaluate the existing system and provide repairs and enhancements as needed to ensure methane issues are mitigated and the system is working properly. The implementation date is May 31, 2016.

Regarding recommendation 2, management stated a maintenance contract will be established with a qualified vendor to provide periodic evaluations of the system to ensure the system is working properly and that methane levels do not exceed the permissible levels. The implementation date is October 31, 2016.

This is poor building design! The Metroplex complex is built over huge methane field. The runoff from the complex roof feeds the ground contamination. The extra water helps feed the contamination and create more methane.

Then large parking lots were built around the complex. This is putting a cover over the field and the parking lots funnel the escaping gas to the complex foundation. This is al taking place in the middle of the field.

Weather conditions will cause toxic gases to remain close to the ground and concentrate in lethal doses in a dome over the complex. Fresh air will need to be forced into the building from areas far outside the brownfield area.

This problem has been happening in nature. Bison are overcome by gas under certain weather conditions. The gas builds up in valley’s and oxygen depletion takes place.

I’m surprised engineers didn’t consider this problem.

36 yrs of safety talks from jackass bosses who did care about any 1 but the ass hole telling them it was there job to tell the lie or get moved out . Always remember that it is postal way. Good bosses get F like the good workers. The crap rises to the top and you wonder about the decisions that are made. God Bless all those who still have to put in the time

I feel for you all. From a lucky retired postal carrier/ clerk/ lobby director

Sounds simular to a situation in California called Porter Ranch!

This methane gas is no joke and in my opinion shouldn’t be built on top of at any cost!

But I guess as long as they don’t start contracting their drinking water from someone else they’ll be okay.

Why would anyone approve this site for a facility?

Someone had to make a lot of money when it sold.

Who is responsible for this mess? Which tool or

thug sitting in a clean air conditioned office is responsible?

Makes you think!!!! Fire them all

Upper management new about this along time ago. If this is true, they should be held accountable. Jail time! Just like the murdering bitches they are. Worst managers I’ve ever seen. Typical government protocol. SCUM!

The main question is why the USPS built this facility on brownfield in the first place. They could have picked a better location and saved money on sensors and other equipment, but no, they went ahead and put the office on a location known to have methane emissions.

If any of the five deaths can eventually be connected to methane poisoning, the unions must sue vigorously, and they should have called the EPA and OSHA when they found out the USPS’ intentions. Management knew there were sensor problems and did nothing. So typical.

This is another example of incompetence at higher levels. Not that all management is bad, or inept, but all it takes on the ladder is one rung occupied by an idiot who thinks they know everything and any attempts to get anything through to that person or past is impossible. We have a situation I can’t comment on other than to say the safety of the employees is an issue, and a supervisor exacerbated the whole thing in a CYA scheme.

But we have to deal with another problem that I dealt with time and time again as a branch officer: even when conditions are deplorable due to managerial abuses of every kind imaginable, be it harassment, behavior problems, severe safety problems that go ignored or whatever, it is almost impossible to get craft employees to stand up for themselves. They fear retribution, which is not unfounded, or just don’t want to make trouble regardless of how victimized they are, or are just plain lazy and bitch all day but will not do anything the steward suggests.

Management bets on this situation. They will intimidate, over supervise and otherwise harass anybody who doesn’t stand their ground, and the CCA program has become abuse heaven for piece of shit managers who know they can run the CCA’s ragged, and the threat of being released after their term is up is enough to keep them quiet. What’s worse is when CCA’s go regular, they seem to be unable to grasp they are not CCA’s any more, and continue to work as if they were, with little thought of route maintenance, being more involved in their union, and are nationally in the process of eventually seeing thousands of routes eliminated when the first national counts happen in a few years after some of us slowhands retire. Management is biding their time. No sense in a count right now – with the parcels going through the roof, as long as we career old farts are around it would mean route cuts, and that’s not their style.

Like the methane leak problem, if you as a relatively new carrier want to have a reasonable route, supervision that knows that you are not on an OTDL list, and be treated with respect, you have to take the initiative. Know your rights and exercise them or you’ll be pounded into the ground faster than we old carriers were.

We will replace you with a cheap labor if you die because of it.