USPS OIG: Vehicle Maintenance Facility Efficiency Nationwide – Capping Report

USPS OIG: Vehicle Maintenance Facility Efficiency Nationwide – Capping Report

Background

The vehicles owned by the U.S. Postal Service represent a capital investment of nearly $3.6 billion. The fleet is maintained using 316 Postal Service vehicle maintenance facilities that service 211,264 vehicles. The Postal Service also contracts with commercial garages throughout the country for maintenance and repair. The vehicle maintenance program mission is to ensure safe, dependable, and economical performance of Postal Service vehicles. In fiscal year (FY) 2014, the Postal Service vehicle maintenance expenses totaled $1.1 billion.

The Postal Service established performance indicators to gauge the effectiveness and efficiency of the vehicle maintenance program. These indicators include overhead and workload management at the maintenance facilities. During FY 2013, we audited facilities in the Capital Metro and Pacific areas and found inefficiencies, mismanaged resources, and inadequate controls.

Our objective was to assess the overall efficiency of vehicle maintenance facility operations in the Eastern, Great Lakes, Northeast, Southern, and Western areas.

What The OIG Found

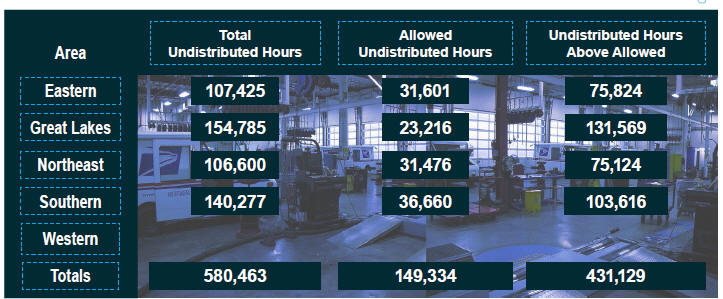

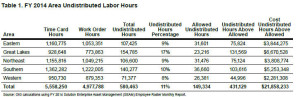

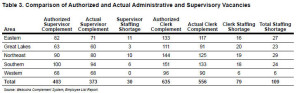

Vehicle maintenance facilities were not operating at peak efficiency and were not efficient when compared to the established targets. Specifically, undistributed labor, work order hours that were more than the timecard hours, was 11 percent of total maintenance labor costs and exceeded the established target of 3 percent. Also, overhead (supervisory and support) labor costs were 24 percent, of total maintenance labor costs, which were lower than the established overhead target of 30 percent. The VMFs had 109 vacant administrative and supervisory positions.

These conditions occurred for several reasons.

These conditions occurred because of management’s lack of oversight in monitoring mechanic workhours, as well as not reaching the workhour targets due to administrative and supervisory vacancies. Improving oversight and right sizing staff at vehicle maintenance facilities would increase overall efficiency, saving the Postal Service 431,129 workhours at a cost of over $21.8 million annually.

Management Oversight. Management did not adequately monitor workhours for mechanics. Also, management was not familiar with the SEAM database reports to monitor mechanic workhours and provide oversight. Per Postal Service policy, supervisors are to maintain all necessary control procedures to ensure maintenance work is performed in a safe manner and related costs are not excessive.6

Staffing Vacancies. Management did not fill vacant positions7, indicating that vacancies are due to retirement and reassignments. Additionally, management indicated mechanic vacancies continue to exist due to new mechanics graduating from vocational schools are not trained to repair older vehicles,8 making it difficult to fill vacancies.

Improving oversight and right sizing staffing at VMFs would increase overall efficiency, saving the Postal Service

431,129 workhours at a cost of over $21.8 million.

What The OIG Recommended

We recommended management reduce 431,129 undistributed workhours for maintenance and repairs. We also recommended management right size staffing at vehicle maintenance facilities to improve operations.

Source: Office of Inspector General | United States Postal Service

USPS conducting survey for outsourcing part of VMFs workload

OIG: Contractors paid over $15m during period of USPS VMF employees getting bribes, kickbacks, lap dances

I say let democrat crony capitalist sen diane feinstein and hubby blum sell them off. they have only made a billion dollars on their no bid postal real estate scam…………….diamonstein would have you believe its pirates and staples who is the problem? diamondstein just get us a 25% increase in 5 years and than you can go back to licking feinstein’s boots.

The lack of managerial oversight is astounding. Setting target pmi schedules on 25+ year old vehicles and throwing money away to contractors to “achieve” these goals is ridiculous. My vmf pays a towing company in excess of $200 per shuttle and get nothing out of the deal extra (eg tag repairs). The lost keys are an added bonus to help make our job harder down the line. If vmf’s were ran by people that had half a brain and gave half a shit, using cost savings as a target goal, the savings would be immense.

near our PD&C there is a UPS vehicle repair shop…….you see them pull motors out of the brown trucks and tractor trailers. they have a car wash type set up so their vehicles are clean machines-have never seen a dirty truck. usps looks like dirty old govt screw up! do you think Obama see the dirty trucks when he is out and about in DC ? He did say thats its always the PO that is screwed up. (youtube) best raise ever for the Post Office was under Republican Richard Milhouse Nixon. Clinton and Obama just 1% woopee.

Oh Yeah…Reduce Mechanic Hours and increase number of Managers?…Are you kidding Me? The Contractors cost the USPS more per hour as proven in the grievance settlements and the OIG works for the USPS…of course their advocating more Managers and less People either in contact with the mail or the Vehicles.

I believe the term you’re looking for is tl;dr.(too long, didn’t read). Why bother posting if you aren’t going to add to the discussion. USPS has fanbois a plenty.

As far as the article goes, it is sadly and grossly misguided. I am greatly offended by it. If you want to know why…

tl;dr

The article subtly raises the point that mechanics are mindless robots that are corrupt and incompetent without the guiding light of supervision. This kind of thinking is the very thing that will add leg weights to production from these facilities.

1) Seam is barely functional, let alone the “gold standard” that it’s made out to be. The software was something that Oracle had sitting on a shelf since the late 90’s. It is archaic, has poor search functions and the interface is cumbersome.

2) The amount of undistributed labor is a poor guide line for “efficiency”. Because Seam tries pigeon hole mechanical work(which is all but impossible), time must be put in undistributed labor to at least have some accountability of the time. Part of what is considered undistributed labor, is shuttle time. Do you consider shuttle time a waste of USPS resources? Somebody needs to do their homework instead of firing from the hip with accusations of corruption and incompetence.

3) On average there is about 2% of the fleet that needs repairs outside of normal preventive maintenance. A small portion of that 2% is an actual breakdown. So 98% of the time, everything goes as it is supposed to, I hardly find that inefficient. The fact that this behemoth corporation manages to function as well as it does, is impressive. People expect to receive their mail every day….”expect”…..not “hope”. Mechanics are a vital link in the ability to achieve this. For the most part they are invisible, which is preferred. The only time mechanics aren’t invisible is when things are going wrong.

4) To think that a bigger stick is going to keep mules in line is a mistake. Mechanics are tradesmen, aka skilled labor. When it comes to skilled labor, you need them more than they need you. Do you stand over a roofer while he is roofing your house? Do you think that if you did you would get it done quicker and better? What would happen is he would become resentful and do shoddy work. There is an adage among mechanics that goes something like this. The price to get your car fixed is $25 an hour, $35 an hour if watch and $50 an hour if you help. When dealing with skilled labor, a bigger stick just makes the job take longer. A good mechanic supervisor is more dispatcher than overseer. It’s also why as a private citizen, you need a doctor, mechanic, plumber, electrician etc. that you can trust, because you are vulnerable to these people.

5) The report that this article heavily relies on is also the very reason the fleet is not as good as it could be. Upper management presses for numbers that make them look good and increase their upward mobility. However they fail to supply the necessary resources to make those numbers happen. The result is a fleet that is partially patched in a poor attempt to do more with less. This results in moderate to severe “breakdown” maintenance. In other words, instead of being able to prevent breakdowns, mechanics are forced to do the “preventive” maintenance when the truck finally can no longer be patched and must actually be repaired. This is where the inefficiency lies. Impossible to fix under the current corporate structure, unless you have a manager that has no desires for upward mobility, which is highly unlikely.

In closing, if this article is just a justification to make the USPS more top heavy, be my guest. Just put the blame where it belongs.

Twisted Wrench:

The VMFs managers are idiots for the most part. They hold no one accountable for their work order hours. Just sit and watch while some workers do absolutely nothing. Its a crying shame the Postal Service has put these idiots in the position they are in. Making big bucks and don’t have a clue what’s going on. I bet half of them couldn’t even make it at Mickey D’s without getting fired. The VMF’s are being run in the ground by these idiots and I wonder how much longer it will last. Till upper management gets their head out of there arse and holds managers responsible nothing will change. Oh and the vehicles , that’s another thing , they are way past worn out. The PO keeps dumping money in them instead of migrating new vehicles in. Cant they understand the money they are throwing away on the fleet we have now is ridiculous. Oh did I mention the VMF’s are ran by idiots?

Unfortunately there is not enough help in VMFs and postal mis management runs rampant! How come it takes years for them to find out contractors are ripping us off?! By then we have lost tons of money. Why don’t managers and supervisors do their jobs properly? If they don’t, do you think the workers will? No one cares to ask the VMF employees their opinion on straightening things out. Some one sitting in a chair in an office makes descisions for shit they know nothing about! Sound familiar??? Until there are people in the right places who care, forget getting things right. It’s business as usual!!!!!!!

concerned Postal worker • a few seconds ago

Sourcing out vehicle maint is being done in Westchester NY The quality of the work is horrendous and the prices outrageous. They just keep force feeding these so called “private vmf’s” regardless of costs. 150%-200% markup the norm on parts , labor charge through the roof,and some repairs may not even be done ,but we are being charged. No oversight what so ever. One company with many shell corporations. Repairs and Pmi’s on one bill and the outrageous tow charge on another. That’s right same company does towing under other name. No tow charge on invoice to offices, big tow charges on national tow contract. PMs don’t even know what the tow costs are because tow charges are paid on another contract. OIG are you listening, it’s time somebody outside VMF looks into this!!!!!

Contract out vehicle maintenance. There only 5,250 VMF employees anyway so just excess all of them and be done with it. Got to start somewhere and vehicle maintenance would affect the fewest employees. Next, get rid of field maintenance. Another 5,000 or so employees that could be excessed without too much trouble. After that, plant maintenance could be contracted out. Too many custodians, mechanics and ETs just sitting around taking up space where an energized contract technical labor force could be working.

Our VMF person just jockeys the LLVs to the different repair shops! And out of the last 10 years I have only seen him actually work on 1 (ONE) LLV and it was something simple….hell the guy won’t even put air in the tires!

In our office Custodians not Mechanics are told to work on the LLVs & drop the broom. This leaves another temporary fix for another “mechanical” problem & a dirty facility !! Additionally MNGT. chooses the cheapest contracts which results in someone that should not touch the LLV to result in more breakdowns etc. OH!! but it helps the budget! I NEED A BONUS !!

how productive is it when the carriers truck breaks down? these trucks suck! replace them now! any moron should know that. oh, wait…we are talking about postal mgt……nevermind!

Yet another example of management incompetence. Losing $22 million a year is ridiculous. The fleet is decrepit, the LLV’s are death traps, and now because of the much larger parcel business, they’re too small. Carriers have to crouch around in the loading area, parcels fall all over the place and we have to constantly rearrange them so we won’t overlook them on the route. Plus the fact they break down all the time, ruin tires and have terrible performance just shows you how indifferent the USPS is to their own fleet. If they’re wasting $22 million a year, that could be used to phase in new vehicles. Or hire enough VMF help.

Our “mechanic”, and I use the term loosely, has been told twice by me lately that my truck is running terrible and the “check engine” light stays on, but his reaction? “It still runs, don’t it?” Gee, thanks for caring. This is the same person who decided to hose down and clean the insides of the fleet one morning when it was 15 degrees and locked the inside of the LLV’s in solid ice.

Maybe I ought to write a book after retiring detailing postal stupidity but it would be so long I’d never finish it if I got half the contributions from other craft people I suspect I would.

Dear Cynical-

Don’t bother writing a book–your posts are so long I fall asleep trying to read them. We do not need cynical thoughts we just need to get along and function like the great entity we are. We have all the tools and we have all the right stuff1