USPS OIG -Managing Package Growth – Southern Area – Management Advisory Report

This report presents the results of our audit of package growth in city delivery operations in the Southern Area . Our objective was to assess the Southern Area’s package growth management strategies in city delivery

operations. U.S. Postal Service shipping and packages volume is expected to grow 13 percent, to 4.5 billion pieces in 2015, resulting from the strong year-over-year growth in e-commerce and the Postal Service’s own growth initiatives. Priority Mail®, Parcel Select®, and First-Class® package service, the three largest shipping and packages categories, are expected to grow by double-digit rates, driven by their highly competitive prices and consistent, reliable services.

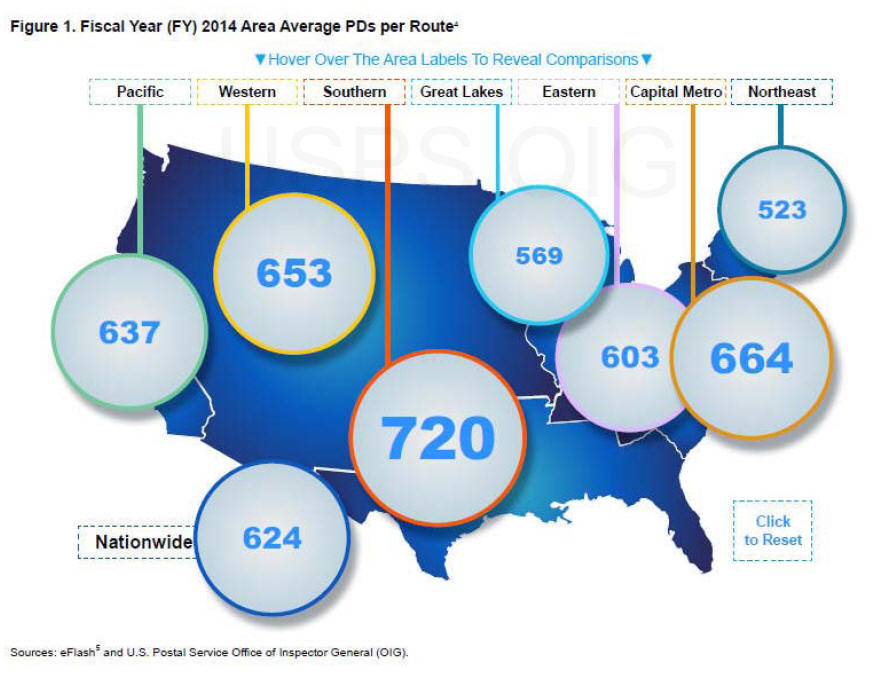

The Southern Area covers Alabama, Arkansas, Florida, Louisiana, Mississippi, Oklahoma, Texas and portions of Georgia and South Carolina. City Delivery Operations in the Southern Area includes over 24,000 city delivery routes with over 17 million possible deliveries3 (PD), an average of 720 PDs per route. The PD average per route is 15 percent higher than the national average of 624, and the highest average of all areas

The Southern Area had a 13 percent growth in packages on city delivery routes, increasing from 150 million in FY 2013 to 170 million in FY 2014.

Conclusion

The Southern Area implemented strategies in their districts to manage increased package volumes in city delivery operations.Their strategies included redesigning workroom floor space, maximizing delivery vehicle capacity, and utilizing an alternate package delivery option during the holiday season. Management has available data to monitor routes in real-time, and to forecast volumes. They can also use flexibility when making operational decisions to manage the expected continued package growth

Delivery Vehicle Capacity.

Due to limited vehicle capacity, management stated that carriers sometimes left their routes to return to the delivery unit for more packages. They did this because their delivery vehicles were not large enough to accommodate all of the packages scheduled for delivery on their route that day. We did not observe carriers making multiple trips during our 5 days of site visits.8 Furthermore, to accommodate increased package volumes on routes, delivery supervisors also used a pivoting feature in the Delivery Operations Information System9 which transfers a portion of a route’s street deliveries to one or more carriers for that day. Additionally, we observed carriers loading their vehicles to full capacity to accommodate their total mail volume for the day (see Figure 5).

Future Opportunities

There are strategies that the Southern Area could pursue in the future to help manage increased package growth. According to Southern Area management, additional funding is required for implementation. These strategies include gopost® locker units, next generation mail boxes and delivery unit automated sortation equipment

In response to recommendation 5, area officials agreed to reallocate existing larger vehicles to units with high package volumes.Officials stated that this is a continual process to review existing vehicle utilization, and reallocate larger vehicles throughout the area in delivery from city/rural routes to high parcel volume operations thereby managing costs and increasing carrier street efficiency. Officials further stated that movement of vehicles must be cost effective and suitable, taking into consideration the age of the existing fleet and any possible modifications which will save time and reduce instances of carriers having to return to the unit for additional volumes. The target implementation date is January 1, 2016.

No one has mentioned the fact that Amazon will use a huge box for a very small item. Why? Because the USPS doesn’t charge “dim weight”!!!! That’s right, they wanted the contract so bad, that they said, “use any size box you want, we don’t care that we can’t fit them all in our trucks! We just want the contract, even though in the end, we will be lucky to break even!”

!!!!!

Once again the management at the USPS can’t solve a problem the easy way. Why can’t they just give these offices an extra vehicle and create a position for a carrier to just handle parcel delivery and pick ups? Why do we need to waste more money on bigger trucks that will be much more difficult to drive safely on busy city streets?

er…………its called a UPS delivery vehicle. not to hard to figure out is it. notice they are always clean and no rust. why don’t we just get it over with and have UPS buy us out…….po mismanagers will be considered surplus and put to the curb.

By all means, we need more management involvement. Their own vision of their importance and intelligence is astounding as it is false.

Let’s think about this for second: a previous OIG report blamed everything they found “wrong” in greater San Diego on carriers (of course), barely holding management accountable for anything. Now they say management can monitor routes in real-time, meaning minute by minute micromanaging that can only interfere with the work that’s needed to be done and give zealous ass kisser supervisors more and more excuses to issue discipline that is not needed, just to make themselves feel like big shots and lord it over the carriers.

But carriers only do what they’re instructed to do, and have no input on how to improve service, no matter how management tries to snow you with their idiotic employee surveys that never ask any relevant questions. Even a supervisor or PM with a sympathetic ear who understands the people who know the job best are the ones doing it are helpless as they are overridden by maniacal POOMS and Districts, who tell them right down the minute how do to absolutely everything, which some might say renders their jobs unnecessary.

So we use beat up pieces of shit with decals worn off, paint worn off showing the gray primer coat, constant breakdowns, dents, scratches, etc. LLV’s were nice for the first ten or so years, but now they look and handle horribly. I understand we must be concerned with more than aesthetics, but the millions on useless crap could have gone to an up to date delivery vehicle a long time ago.

New trucks must be larger in loading space, need racks, higher roofs and a uniform chassis that has front and rear axles aligned properly instead of replacing good tires every three months. Front wheel drive would help, and reduce having to use chains as often, the list goes on. As I retire at the end of next year, I’ll not get to see or drive a new vehicle, but it’s high time we looked the part to match those fancy stupid commercials we waste money on. How do you expect to look like a great technological company with modern amenities when you’re driving a scrap heap Jed Clampitt wouldn’t be caught dead in?

From a quick glance those LLVs look like the Ford Explorer based ones

with all wheel drive.

Why don’t they ship some of those up here to the Northeast where

we actually need all-wheel drive.

Then slowly buy new ones for that area of the country.

Wait, making too much sense.

Sorry.

I’m worried that a larger truck will be harder to deliver mail out of when you have tight cul-de-sacs. Something like a 2 ton truck would never be able to turn in tight cul-de-sacs. However the existing trucks would be 1000 times better if management would only put racks in the back of the trucks to help us sort packages. It’s a pain in the ass to try and organize parcels in the back of the trucks when you have no Racks. You basically have a flatbed truck with trays of mail on the bottom and parcel stacked on top. So when you need a new trays of mail, you have to move the packages off of it and then replace him wasting time. When you come to a new street, you have to bring all the parcels from the back to the front to deliver them. you’re constantly moving packages back-and-forth in the bank trying to get the ones you need first. Those trucks that have racks in the back, at our station there’s only three, delivery time is decreased by 30 minutes per day because the carriers have room to work. We had a loaner truck at our station with racks in it and everybody was fighting for it because it makes delivering mail more organized and easier to do. However our illustrious postmaster, who always claims they carried mail before, says it doesn’t make any difference. This person doesn’t want to spend precious money to save money because they want to impress their bosses to get a bonus. I always send report saying look how much I saved our company give me a bonus. Yes packages are heavy. No management will spend money given us Rexon our trucks. So I’m smiling heading to the bank with all the overtime of making. What management doesn’t understand is this simple truth. The larger the truck, the longer it will take to deliver routes because they’re harder to drive. I’ve had the same route for 35 years. I used to drive a small jeep. When we went to the larger trucks, it started taking me 30 minutes more to deliver my route. It was cut back down to an eight hour route. Now with the new larger trucks they plan on buying, with all the cul-de-sacs I have, it’s going to take me even longer and there’s nothing management could do about it because you have to drive safe. The simple solution to the problem would be to put racks in the back of the trucks we have so we can have the parcels sorted and better organized. Or yes, buy new trucks because our engines are wearing out. But don’t buy a huge tractor-trailer and expect because it’s bigger and can hold more mail that you can move quickly in them. Nice thing is I’ll be retired before I ever see them

WoW! Going from a 1/4 ton Jeep to an LLV caused an extra 30 minutes of drive time!! Either you are a pro at wasting time or such an incompetent driver you should not have a license.